Chip on board | Read the car regulations in one article

Why is it so difficult to enter the automotive supply chain

Why is the industry so demanding on automotive chips? A fundamental starting point: automotive chips need to operate normally without failure in ambient temperatures as low as -40° up to 125°, and in a design life of up to 15 years. Once the problem occurs, endangering personal safety and property security.

Therefore, the chip on board first needs to obtain two tickets in the development stage

- AEC Q100 certification:

- 2.Functional safety (ASIL feature)

AEC Q100 certification

Function: Ensure product reliability indicators for proper operation in various harsh environments

So how is this achieved?

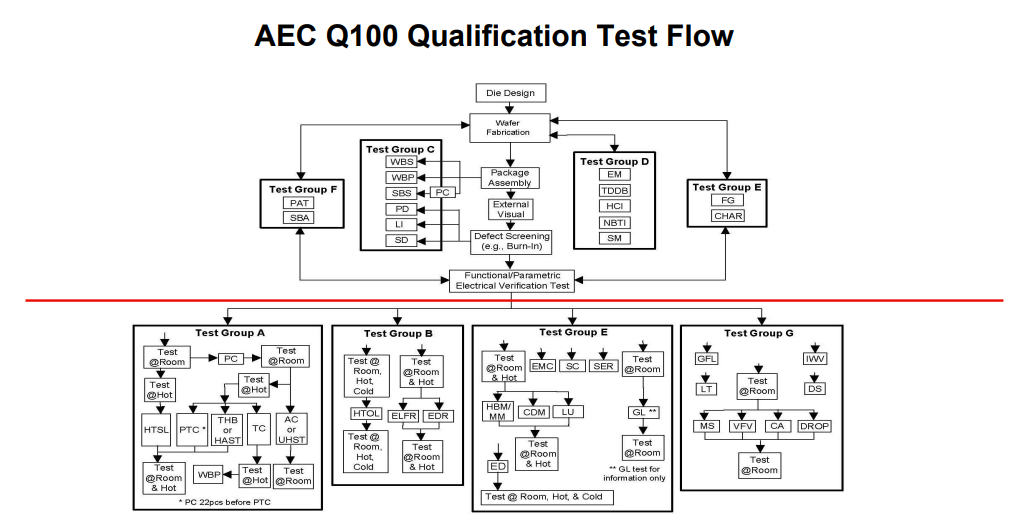

AEC Q100 specifies a series of test verifications, such as environmental stress acceleration test, service life simulation test, electrical characteristics confirmation test, package depression integration test, and wafer process reliability test.

/Trivia/

The above AEC Q100 verification is usually done in-house by chip vendors or in collaboration with the supply chain to complete on their own. Manufacturers can claim that their products have passed the AEC Q100 certification after completing the items required by AEC Q100, without the need for a professional third-party architecture audit certification.

Since AEC Q100 certification does not require third-party certification, how can we evaluate the accuracy and validity of a manufacturer’s independent verification process and results? One of the best ways is to look at the actual quality data feedback after mass production.

This is why automotive OEMs look for experience in mass production when selecting suppliers. A product that only claims to pass AEC Q100, without the corresponding quality data supporting the KK-level shipments, it is difficult to gain the trust of OEMs and TIer-1 car manufacturers. It is reported that domestic friendly products for vehicle specifications have not yet a large number of mass production quality data to prove and support, reliability is difficult to guarantee.

Functional Safety

If AEC Q100 is designed to ensure product reliability, functional safety ensures product safety. You can’t have one without the other.

ISO 26262 defines functional safety as

The absence of unreasonable risk caused by hazards resulting from the malfunctioning behavior of electronic and electrical systems.

In other words, functional safety can avoid unacceptable risks caused by the functional failure of the system by introducing safety mechanisms.

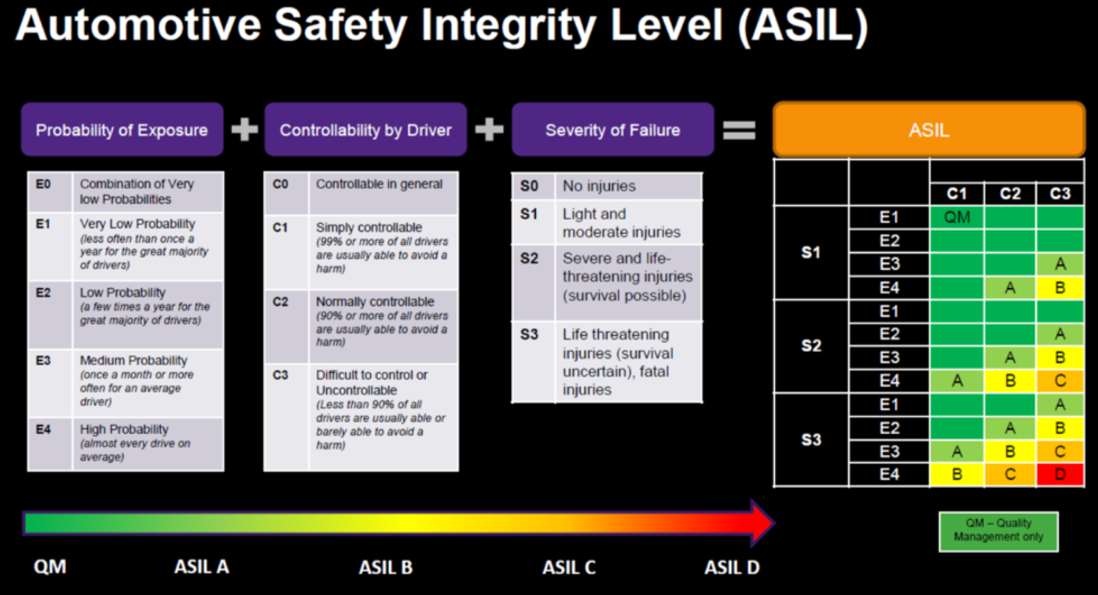

ISO26262 classifies the functional safety objectives into 5 levels: Quality Management only, ASIL A, ASIL B, ASIL C, ASIL D.

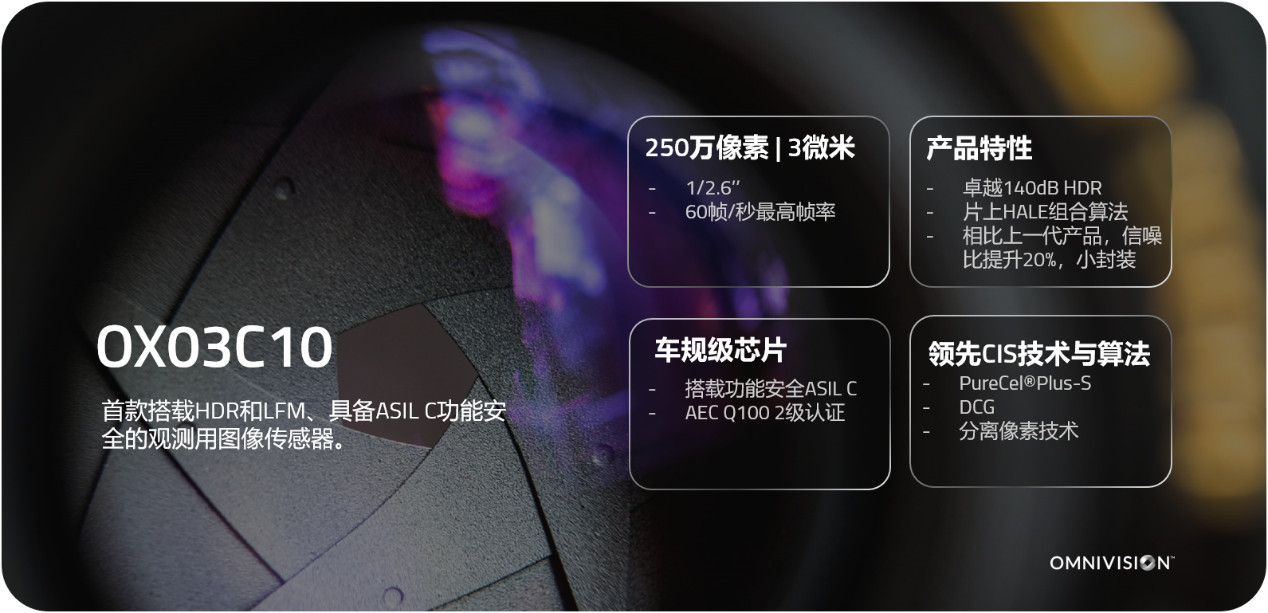

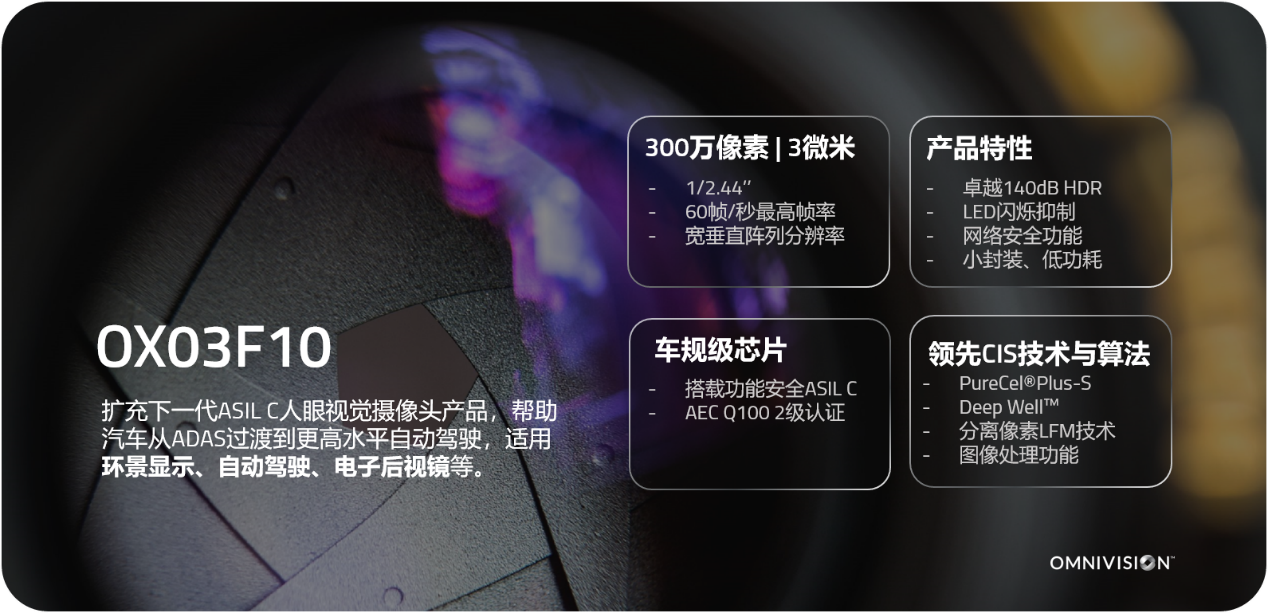

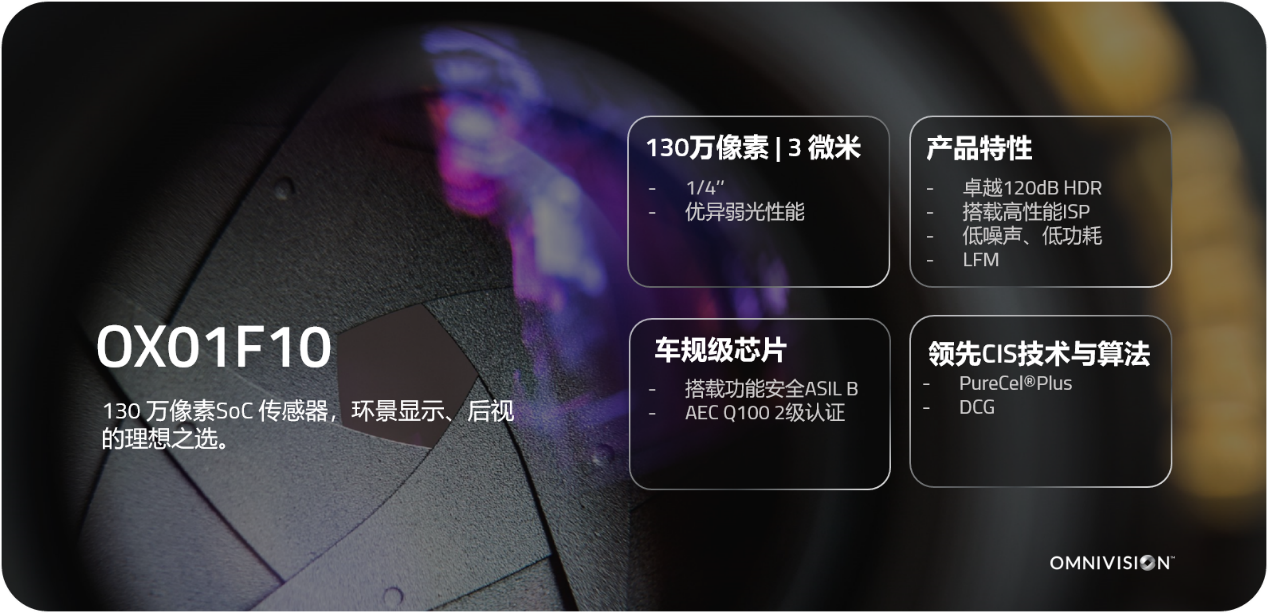

With the technological development of intelligent and networked cars, a new challenge and higher requirements are put forward for the functional safety of cars. Howell Group is the only domestic supplier that can mass-produce ASIL B and ASIL C certified automotive products, other friendly products in the industry either do not support functional safety or are not mass-produced and lack verification.

Howell ASIL C full series solutions

Howell ASIL B full range of solutions

Why are so few products introducing functional security?

The introduction of functional security is a great test of a company’s design capabilities, requiring careful design, from the development of security plans, design security objectives, to the design of security features, Fault InjecTIon and so on. ASIL C is exponentially more difficult to design than ASIL B.

And different companies have different functional safety Know-How, whether the certification results are accurate and reliable, also rely on mass production data verification. And most companies lack the opportunity of mass production verification.

In the field of functional safety, Howell Group, as an image sensor leader, has three major advantages.

Experienced:

17 years of experience in developing a full range of QM, ASIL B and ASIL-C products for vehicles

Market Validation:

Cumulative global shipments of in-vehicle CIS exceed 1 billion units and are widely used by OEMs and TIer-1s worldwide

Product Enrichment:

We offer a large number of ASIL B products as well as ASIL C products for the next generation of camera upgrades.

Howell Automotive CIS is all about safety. Howell Group will continue to introduce innovative solutions that are highly reliable, functionally safe and meet market needs.