Choosing a temperature sensing product may seem trivial, but the variety of products available can make the task quite daunting. In this blog post, I will introduce four types of temperature sensors (resistive temperature detectors (RTDs), thermocouples, thermistors, and integrated circuit (IC) sensors with digital and analog interfaces) and discuss the pros and cons of each.

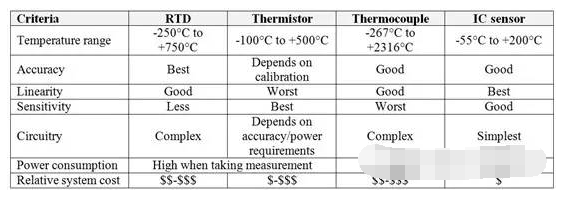

From a system-level standpoint, the suitability of a temperature sensor for your application will depend on the desired temperature range, accuracy, linearity, solution cost, functionality, power consumption, solution size, mounting method (surface mount versus through-hole cartridge and off-board mounting), and ease of design of the necessary support circuitry.

RTD

When the resistance of the RTD is measured while changing its temperature, the response is almost linear, behaving like a resistor. As shown in Figure 1, the resistance curve of this RTD is not perfectly linear, but has a few degrees of deviation (a straight line is shown for reference) – but is highly predictable and repeatable. To compensate for this slight nonlinearity, most designers digitize the measured resistance values and use a lookup table within the microcontroller to apply a correction factor. This repeatability and stability over a wide temperature range (approximately -250°C to +750°C) makes RTDs extremely useful in high precision applications, including measuring the temperature of liquids or gases in pipes and large vessels.

The complexity of the circuitry used to process RTD analog signals varies essentially depending on the application. Components such as amplifiers and analog-to-digital converters (ADCs), which generate their own errors, are essential. The sensor is powered only when necessary for the measurement – you can also achieve low-power operation by this method, but it makes the circuit much more complex. Moreover, the power required to energize the sensor raises its internal temperature, which affects measurement accuracy. With just a few milliamps of current, this self-heating effect can produce temperature errors (these errors are correctable, but require further discretion). Also, keep in mind that the cost of a wire-wound platinum RTD or thin-film RTD can be quite high, especially when compared to the cost of an IC sensor.

Thermistors

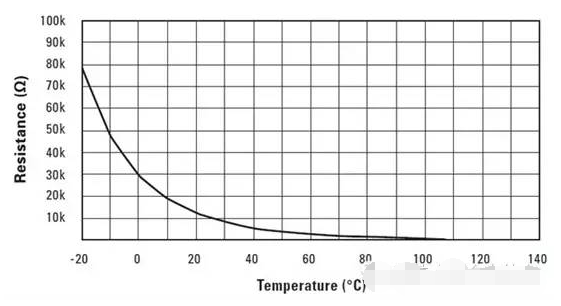

Thermistors are another type of resistive sensor. There is a wide variety of thermistors available, ranging from inexpensive products to high precision products. Low-cost, low-precision thermistors perform simple measurement or threshold detection functions – these resistors require multiple components (such as comparators, references, and discrete resistors), but are very inexpensive and have non-linear resistance-temperature properties, as shown in Figure 2. If you need to measure a wide range of temperatures, you will need to do a lot of linearization work. Calibration of several temperature points may be necessary. To achieve higher accuracy, more expensive and tighter tolerance thermistor arrays are available to help solve this nonlinearity challenge, but such arrays are typically less sensitive than a single thermistor.

Because of the added complexity and cost of multi-jump point systems, low-cost thermistors are generally used only in applications with minimal functional requirements, including toasters, coffee makers, refrigerators, and hair dryers. In addition, thermistors can suffer from self-heating problems (usually at higher temperatures, when they have lower resistance). As is the case with RTDs, no fundamental reason has been found for not being able to use thermistors at low supply voltages — but keep in mind that the lower the full-scale output, the lower the sensitivity of the system it translates directly into based on the analog-to-digital converter (ADC) characteristics. Low power applications also require increased circuit complexity to be able to be very sensitive to noise induced errors. Thermistors can operate over a temperature range of -100°C to +500°C, although most thermistors are rated for a maximum operating temperature range of +100°C to +150°C.

Thermocouples

A thermocouple consists of a contact of two wires made of different materials. For example, a type J thermocouple is made of iron and copperconstant. As shown in Figure 3, contact 1 is located at the temperature to be measured, while contact 2 and contact 3 are placed at different temperatures determined with the LM35 analog temperature sensor. The output voltage is approximately proportional to the difference between these two temperature values.

Because the sensitivity of thermocouples is quite low (on the order of tens of microvolts per degree Celsius), you will need low offset amplifiers to produce a usable output voltage. In the operating range of thermocouples, nonlinearities in the temperature-to-voltage transfer function often require compensation circuits or look-up tables, as is the case with RTDs and thermocouples. However, despite these drawbacks, thermocouples are still very popular, especially for ovens, water heaters, furnaces, test equipment and other industrial processes – due to their low thermal mass and wide operating temperature range (which extends beyond 2300°C).

IC Sensors

IC sensors can operate over a temperature range of -55°C to +150°C – a select few IC sensors can operate up to +200°C. There are various types of integrated IC sensors, but the four most common integrated IC sensors are analog output devices, digital interface devices, remote temperature sensors, and those with thermostat functions (temperature switches). Analog output devices (typically voltage outputs, but some also have current outputs) are most like passive solutions when they require an ADC to digitize the output signal. Digital interface devices most often use a two-wire interface (I2C or PMBus) and have a built-in ADC.

In addition to also including a local temperature sensor, remote temperature sensors have one or more inputs to monitor the remote diode temperature — they are most often placed in highly integrated digital ICs (e.g., processors or field-programmable gate arrays [FPGAs]). A thermostat can provide a simple alarm when a temperature threshold is reached.

There are many benefits to using IC sensors, including: low power consumption; the availability of products in small packages (some as small as 0.8mm x 0.8mm); and also low device cost in some applications. In addition, since IC sensors are calibrated during production testing, there is no need for further calibration. They are commonly used in fitness tracking applications, wearable products, computing systems, data loggers, and automotive applications.

Experienced board designers will use the most appropriate solution based on the end product requirements. Table 1 shows the relative advantages/disadvantages of each temperature sensor.