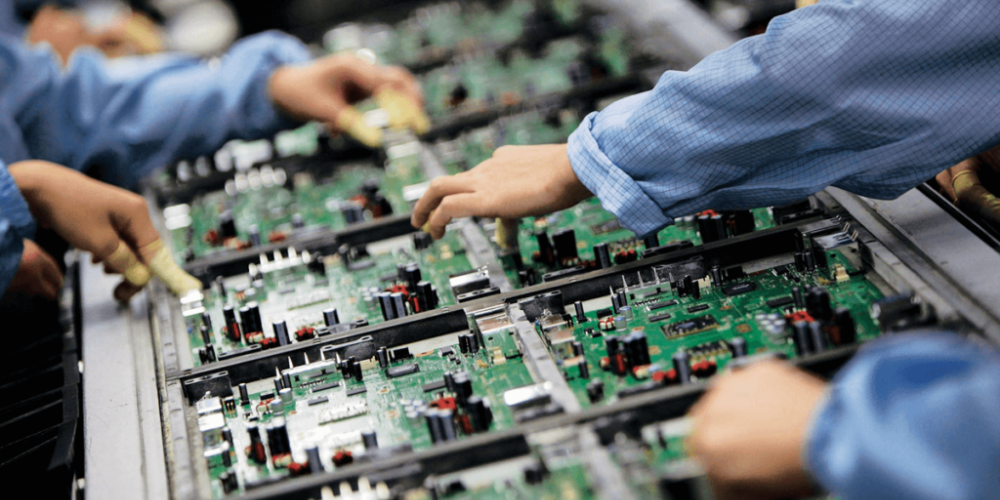

Electronic Manufacturing Services (EMS) play a vital role in the modern world, fulfilling a critical need for various industries. EMS providers offer comprehensive solutions for electronic product design, manufacturing, testing, and distribution. These specialized service providers cater to a wide range of markets, including aerospace, medical, automotive, and telecommunications.

The realm of EMS has evolved dramatically over the last few decades as technological advancements and globalization have transformed the manufacturing landscape. Today, companies continue to seek cutting-edge solutions in order to stay competitive and ensure efficient production processes. Partnering with an EMS provider offers several benefits, such as reduced operational costs, increased flexibility, and access to specialized expertise.

Another essential component of EMS is the focus on quality control and regulatory compliance. Given the highly technical nature of electronic products, a stringent commitment to quality assurance is necessary for ensuring the safety and functionality of the final products. EMS providers adhere to robust, internationally recognized standards to maintain the highest level of quality and reliability in their services.

Overview of Electronic Manufacturing Services

Electronic Manufacturing Services (EMS) encompass a wide range of value-added services provided to Original Equipment Manufacturers (OEMs) concerning complete assembly, design, and testing of electronic components and systems. These services enable OEMs to focus on their core competencies, such as research and development, sales, and marketing, while outsourcing the manufacturing aspects to external providers.

History and Evolution

The EMS industry has grown significantly since its inception in the 1960s. Initially, EMS providers offered basic assembly services, but they have evolved over the years to provide more comprehensive offerings. In the 1980s and 1990s, the shift towards globalization allowed EMS companies to expand their operations across continents, resulting in cost-efficiency and increased production capacity.

Technological advancements in the 2000s further propelled the EMS industry by introducing new manufacturing processes like surface mount technology, automated assembly lines, and advanced testing equipment. Today, EMS providers not only cater to the electronics industry but also to automotive, aerospace, and medical sectors, offering sophisticated services such as design, supply chain management, and after-sales support.

Key Players in the Market

The EMS market comprises several key players, each with a unique set of capabilities and regional presence. Some of the prominent companies in the EMS industry include:

-

Foxconn: The largest EMS provider in the world, Foxconn is a Taiwan-based company that specializes in manufacturing electronics for prominent brands like Apple, Dell, and Sony.

-

Jabil Circuit: Headquartered in the United States, Jabil Circuit is a global EMS provider known for its innovative manufacturing processes and expertise in the medical, aerospace, and automotive sectors.

-

Flex Ltd.: Singapore-based Flex is a leading EMS provider with a strong presence in various industries and a commitment to environmental sustainability.

-

Pegatron: Another major EMS provider from Taiwan, Pegatron has an extensive history in the electronics industry, providing services to well-known brands like Microsoft, Asus, and Apple.

Types of Electronic Manufacturing Services

Design and Engineering Services

Design and Engineering Services are essential for creating innovative electronic products. These services include:

- Concept development: Transforming ideas into viable products with market potential.

- Schematic design: Creating detailed blueprints of electronic circuits and components.

- PCB design: Designing the layout of printed circuit boards, ensuring optimal performance and manufacturability.

- Prototyping: Building and refining early-stage product models to test functionality, performance, and durability.

Manufacturing and Assembly

Manufacturing and Assembly involve turning the design files into physical products, which includes:

- PCB fabrication: Producing printed circuit boards according to design specifications.

- Component sourcing: Procuring electronic components necessary for product assembly.

- SMT and through-hole assembly: Attaching components to PCBs using surface-mount technology (SMT) or through-hole methods.

- Box build assembly: Integrating PCBs and other components into enclosures, ensuring proper fit and function.

Testing and Quality Assurance

Testing and Quality Assurance involve various steps to ensure product reliability and compliance, such as:

- In-circuit testing (ICT): Verifying electrical performance is within acceptable parameters.

- Functional testing: Confirming the device operates as intended and meets performance requirements.

- Environmental stress testing: Exposing products to extreme temperatures, humidity, and vibration to evaluate durability.

- Compliance testing: Ensuring products adhere to industry standards and regulations, such as RoHS or FCC requirements.

Logistics and Supply Chain Management

Logistics and Supply Chain Management facilitate the movement of products and components throughout the manufacturing process:

- Inventory management: Tracking component stock levels, minimizing lead times, and maintaining accurate records.

- Order fulfilment: Packaging and shipping completed products according to customer requirements.

- Reverse logistics: Managing returns, warranty repairs, and recycling of components.

- Supply chain optimization: Streamlining processes to reduce costs, improve efficiency, and promote sustainability.

Applications and Industries Served

In the world of electronic manufacturing services (EMS), various industries rely on the expertise and capabilities of EMS providers to bring their products to life. The following sub-sections detail a few industries that widely use EMS:

Aerospace and Defense

Aerospace and defense industries require highly reliable, precision-engineered electronic components. The EMS providers in this sector offer specialized services such as:

- Design and development

- Printed Circuit Board (PCB) assembly

- System integration and testing

These components are often subject to stringent quality and safety standards, including compliance with International Traffic in Arms Regulations (ITAR) and AS9100 certification.

Automotive

The automotive industry increasingly relies on electronic systems for enhanced safety, performance, and comfort. EMS providers in this field produce electronic components and assemblies for:

- Engine control units

- Advanced driver-assistance systems (ADAS)

- Infotainment systems

- Electric vehicles (EV) components

They must adhere to the standards of the International Automotive Task Force (IATF) and be ISO/TS 16949 certified.

Consumer Electronics

The consumer electronics market is ever-evolving, with rapid product development and life cycles. EMS partners in this sector must be agile and adaptable to meet demands. They manufacture products such as:

- Smartphones

- Wearables

- Gaming consoles

- Home appliances

Certifications associated with consumer electronics include ISO 9001, 14001, and 13485.

Medical Devices

The medical devices industry demands high-quality, safe, and reliable electronic components. EMS providers in this sector must adhere to specific regulations and standards such as:

- Food and Drug Administration (FDA) compliance

- ISO 13485 certification

- Good Manufacturing Practices (GMP)

EMS companies support medical device manufacturers from prototyping to assembly and testing, producing parts for:

- Diagnostic equipment

- Surgical instruments

- Patient monitoring systems

Telecommunications

The telecommunications industry relies on cutting-edge, efficient hardware, which EMS firms provide. They manufacture and assemble components for:

- Network infrastructure equipment

- Wireless devices

- Internet of Things (IoT) devices

EMS providers in this sector need to maintain industry-specific certifications and standards such as ISO 9001 and TL 9000.

Benefits and Challenges of Using Electronic Manufacturing Services

Benefits for OEMs

Electronic Manufacturing Services (EMS) provide a range of benefits for Original Equipment Manufacturers (OEMs). Some of these benefits include:

- Cost savings: By outsourcing the manufacturing process to EMS providers, OEMs can significantly reduce their production costs, particularly in labor and overhead expenses.

- Focus on core competencies: Outsourcing manufacturing allows OEMs to focus on their core competencies, such as research, design, and product innovation.

- Access to advanced technology: EMS providers often have access to cutting-edge technologies and equipment, which OEMs can leverage to improve product quality and performance.

- Scalability: EMS providers offer the flexibility to scale production up or down depending on market demand, helping OEMs adapt to changing market conditions more effectively.

- Supply chain management: Proficient EMS providers can manage the entire supply chain, from procuring raw materials to delivering the final product, allowing OEMs to outsource much of the logistics and inventory management tasks.

Challenges and Solutions

While there are numerous advantages to using EMS, some challenges can arise. These challenges, along with potential solutions, are as follows:

- Quality control: Ensuring product quality is essential, and it can be difficult to guarantee when manufacturing is outsourced. To address this issue, OEMs should carefully evaluate potential EMS partners and choose those with strong track records of quality control and adherence to industry standards.

- Intellectual property protection: Protecting proprietary information is a critical concern when working with EMS providers. It’s essential to establish strong agreements and contracts that outline clear expectations for both parties regarding intellectual property and confidentiality.

- Communication: Efficient communication with EMS partners is vital to ensure project success. OEMs should maintain clear and open lines of communication, using technology to facilitate remote collaboration when necessary.

- Lead times: Capacity constraints or unforeseen delays can impact delivery times from EMS providers. To mitigate these risks, OEMs should maintain robust supply chain relationships and work with EMS providers to develop contingency plans and backup strategies for potential disruptions.

In summary, using Electronic Manufacturing Services can bring significant benefits to OEMs, including cost savings, access to advanced technology, and increased focus on their core competencies. However, they must be aware of potential challenges, such as quality control, intellectual property protection, and lead times. By carefully selecting EMS partners and addressing these challenges proactively, OEMs can reap the rewards of outsourcing manufacturing while minimizing potential drawbacks.

Future Trends in Electronic Manufacturing Services

Technological Advancements

With the advancement of technology, Electronic Manufacturing Services (EMS) will continue to evolve. Automation and robotics will play an increasing role in the production process, reducing the need for manual labor and leading to higher-quality products. Additionally, we can expect the integration of smart manufacturing, powered by the Internet of Things (IoT) and machine learning, which will enable real-time monitoring and data analysis for improved efficiency.

Another key trend is the increasing use of 3D printing in the EMS industry, enabling rapid prototyping and the production of complex, customized parts. This technology has the potential to revolutionize manufacturing by allowing for greater design freedom and reduced lead times.

New Opportunities

The EMS industry is also likely to see new opportunities arise as a result of shifting global trends. The rising demand for renewable energy and electric vehicles will drive the need for advanced electronic components and systems, creating new growth opportunities for EMS providers.

Similarly, the growth in wearable technology and smart devices will increase the demand for smaller, more complex electronic products, pushing EMS companies to develop and adopt new techniques and materials. Additionally, the healthcare industry’s increasing dependence on electronic devices will create a growing market for EMS providers in the medical sector.

As a result of these trends, the EMS industry will continue to see significant growth with the potential to expand further as technology advances and new opportunities emerge.