Wire harness terminal is a conductive element that can form a circuit with the corresponding conductive element. Terminals include pins and jacks, which are used for electrical connection. The materials used are good conductors such as copper and its alloys, and their surfaces are silver-plated, gold-plated or tin-plated to improve corrosion resistance, oxidation resistance and rust prevention.

1 Types of terminals

Terminals can be divided into sheet series, cylindrical series and wire connector series according to their shapes. 1) Sheet series terminals are made of H65Y or H70Y, with material thickness of 0.3~0.5. Some components are shown in Figure 2. 2) Cylindrical series terminals are made of H65Y or Qsn6.5-0.1, with material thickness of 0.3~0.4. Some components are shown in Figure 3.

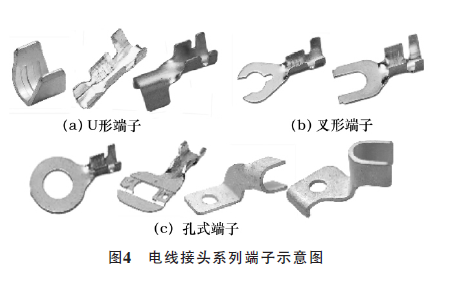

(3) Wire connector series terminals are divided into U-shaped, fork-shaped and hole-type three forms. ① U-shaped terminals using H62Y2, H65Y, H68Y or Qsn6.5-0.1 material, material thickness 0.4 ~ 0.6, part of the component schematic diagram in Figure 4a; ② fork-shaped terminals also known as Y-type terminals, Y-type terminals using H62Y2 material, material thickness 0.4 ~ 0.6, part of the surface nickel-plated treatment, good electrical conductivity, part of the component schematic diagram in Figure 4b; ③ hole-type terminals Generally use H65Y, H65Y2 as the base material, material thickness 0.5 ~ 1.0, part of the component schematic diagram in Figure 4c.

2 The principle of terminal selection

Need to choose different plating terminals according to the different plug parts and different needs. For the higher performance requirements of the equipment, such as airbags, ABS, ECU terminals, etc., should give priority to gold-plated parts to ensure safety and reliability, but for cost considerations, in the premise of meeting the performance requirements can be selected for local gold-plated processing. Specific selection principles are: ① to ensure that the terminal and the selected plug reasonable match. ② for the wire diameter of the crimped wire to select the appropriate terminal. ③ For single-hole waterproof plug, choose the end of the terminal can be crimped waterproof pins. ④Ensure the reliability of the connection. Terminal selection to ensure good contact with electrical parts, plug-in, so that the contact resistance is reduced to a minimum, to improve reliability. Such as: surface contact is better than point contact, pinhole type is better than leaf spring type. In the design to give preference to double spring-type compression structure (contact resistance is very small) of the plug. ⑤ impedance matching. Some signals have impedance matching requirements, especially for RF signals, the impedance matching requirements are more stringent, impedance mismatch will cause signal reflection, thus affecting signal transmission. So in the selection of terminals, be sure to choose the impedance matching terminals. Here, summarize the Japanese terminals can carry current and applicable wire diameter correspondence, waterproof terminals can carry current and applicable wire diameter statistics in Table 5, non-waterproof terminals can carry current and applicable wire diameter statistics in Table 6.