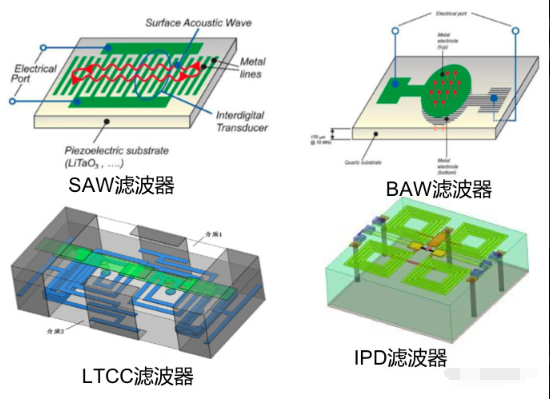

With the advent of 5G, the RF front-end market is growing at a rapid pace, driven by higher frequencies, more carrier aggregation, and MIMO technology. The increase in the number of frequency bands and the increased complexity of 5G RF front ends is driving the demand for miniaturization, with highly integrated configurations making RF front ends more modular than ever. Narrowband filter technologies such as SAW and BAW are as good as in 3G and 4G bands, but they are not well suited to meet the needs of 5G medium and high frequencies and broadband, instead IPD and LTCC are well suited to the task. Therefore, in 5G cell phone RF front-end, it is necessary to choose various filter technologies including IPD, LTCC, SAW and BAW or their combinations to meet the diverse needs of higher frequency, larger bandwidth, and better interpolation loss and out-of-band rejection performance for different application requirements in terms of operating frequency and performance index.

Integrated passive devices (IPDs) are typically processed using advanced wafer fabrication processes, including thin-film processes and photolithography, etc. IPD processes typically require high metal conductivity and high substrate resistivity to achieve high performance passive devices. The high processing accuracy, high yield, mature and stable advanced wafer fabrication processes provide IPD with many advantages: small size, easy integration, high uniformity, low cost, product chain availability and better reliability. As an important technology to realize miniaturized low-cost passive devices, IPD meets the current demand for increasing functionality and integration of RF front-end in various wireless application scenarios for various RF passive devices, including filters, duplexers, baluns, couplers, power dividers, attenuators, etc.

IPD technology, according to the process technology can be divided into thick film process and thin film process, including the thick film process technology using ceramic as the substrate of low temperature co-fired ceramic LTCC (Low Temperature Co-firedCeramics) technology and HDI high density interconnection based PCB printed circuit board buried passive components (Embedded (Passives) technology; and thin film IPD technology, using common semiconductor technology to produce lines and capacitors, resistors and inductors. The following figure shows that the IPD filter and other forms of RF filter implementation comparison.

The figure below shows an IPD bandpass filter that can be used in the 5G band.

IPD Due to the limited market space, the overall market size of IPD is expected to be around USD 600 million by 2025, of which the customized filter market size is USD 360 million. In general, IPD is still in the excavation period, with limited industry players. Currently, it mainly adopts Fabless foundry model, with design-side players including Core and Semiconductor and JOSEPH Micro, and foundries including Lian Ying in Taiwan, China.