LED as a light-emitting devices, need a specific driver circuit to control its current. Generally when the number of light-emitting diodes or diode power consumption is relatively large, it is necessary to drive, and often this driver is several levels of drive, the several levels of drive to an integrated chip, that is, the LED driver IC.

Considering the diverse use of LEDs, designing the best LED driver can be complicated for hardware software designers. Traditional design principles use the total power level of LEDs in a system as an indicator to select different LED drivers. But as the need for dimming capability increases and other requirements emerge, it is important to consider not only the power level but also the topology, efficiency, dimming and color mixing methods when selecting an LED driver.

LED driver different connection, control and dimming methods

According to the way LEDs are connected, typical connections are divided into series LED drivers, parallel LED drivers, and series-parallel LED drivers. The series connection provides very good matching characteristics to the driver, but requires a higher driving voltage. The parallel connection requires less drive voltage, but its matching characteristics are less than 2%. Series-parallel connection combines the advantages of both, for boost controllers such as relatively small drive voltage controller, it is easier to achieve high efficiency, and can be flexibly configured connection, for the source / suction current control of the driver is easier to achieve analog dimming.

Typical LED drive control method one is the source/suction current control we mentioned above, the other is resistance current control, that is, by controlling the voltage on the resistor connected in series with the LED to achieve the purpose of controlling the current, obviously, this control method is only applicable to series-connected LEDs.

The most traditional dimming method is PWM dimming, by adjusting the current duty cycle through the LED to adjust the brightness, we only need to control the LED current channel pass and off to achieve, generally speaking the PWM wave frequency to be greater than 120Hz. even if not a dedicated LED driver, through the PWM dimming can also be easily added to the general-purpose DC/DC converter. Its shortcomings are vulnerable to various types of noise interference, electrical noise, acoustic noise and optical noise can produce a small interference. But certainly PWM dimming with different duty cycle to modulate the average current, you can easily get up to 16-bit resolution, can achieve better results.

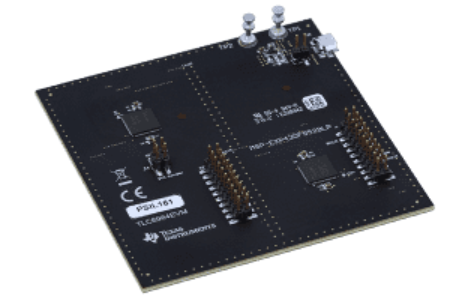

(PWM dimming driver module, TI)

Analog dimming regulates brightness by adjusting the LED current, which varies linearly between 0 and 100% through the LED. Because the LED current is continuous, the power stage of the analog dimming method is easy to handle and there is no noise. Compared with PWM dimming, the same brightness, the analog way of energy efficiency will be higher. In addition, analog dimming has a point that can not be achieved by PWM dimming, analog dimming can adjust the DC forward current flowing through the LED, so it can be used for color calibration to achieve a certain color temperature, such as 6500K white.

How to choose the LED lighting driver?

LED lighting is almost everywhere, and as one of the most efficient light sources, its driver selection requires attention to topology and flexible dimming control, especially for high-power stage applications. The total forward voltage of the LED and the input voltage need to be compared. If the total forward voltage is higher than the input voltage, then a boost topology needs to be selected to meet the voltage requirements, and if it is lower than the input voltage, then a buck topology needs to be used to improve the overall efficiency.

For dimming control, analog dimming and PWM are still the mainstream. In analog dimming can consider using two types of input sources, DC voltage input and PWM input. Using DC voltage input is affected by the voltage accuracy, usually dimming ratio will be relatively low, PWM input can achieve a very high dimming ratio.

(Analog Dimming Driver Module, ADI)

PWM dimming is divided into main FET dimming, series FET dimming and parallel FET dimming. Main FET dimming has the highest rise and fall times, making it difficult to achieve fast dimming and high dimming ratios. Series FET dimming can increase the dimming speed and dimming ratio, while parallel FET is the fastest dimming speed and the highest dimming ratio of a program. If you need faster dimming speed, then parallel FET PWM dimming will be a good choice, if the requirement to minimize flicker, then only from the analog dimming.

Summary

In the development of LEDs we can see that in order to meet higher power density, higher efficiency and smaller packages, LED drivers are becoming more and more integrated and their cost has been comparable to discrete transistor arrays. Some include internal ghosting elimination circuitry in the driver, and are also able to simplify the driver design of dot matrix displays.

Lower EMI is likewise what LED drivers do when possible. The electromagnetic radiation generated by LED drivers can be transmitted either through the power lines or magnetically or capacitively coupled into adjacent circuit segments. These radiations usually do not cause damage, but may cause adjacent circuit components to work improperly. Today’s LED drivers are particularly focused on low electromagnetic radiation, and many LED driver IC manufacturers have used a number of innovations to reduce such risks to the device.