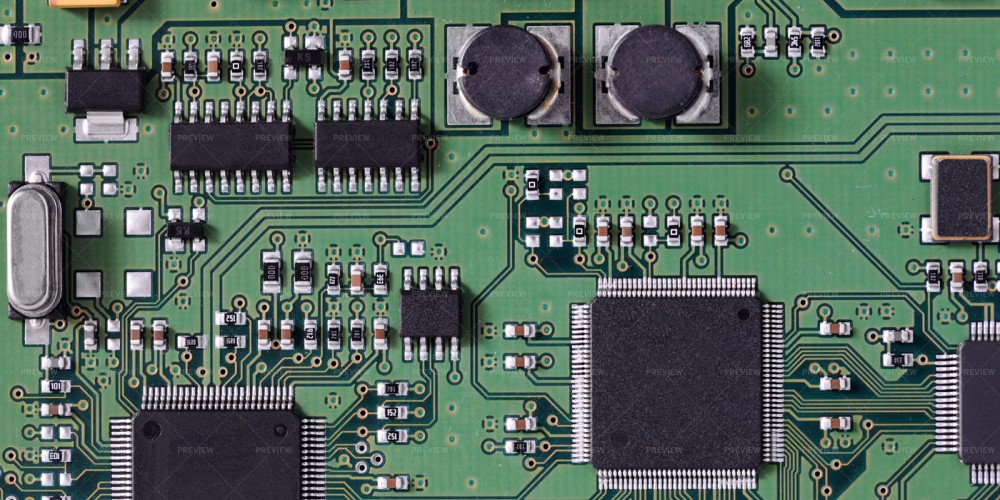

Electronic circuit boards serve as the backbone for many of the gadgets and devices that have become essential in our daily lives. From smartphones and laptops to advanced medical equipment, these boards provide the foundation for effective communication between the numerous electronic components housed within each device. In this article, we’ll delve into what makes these intricately designed boards so vital in modern electronics.

The heart of an electronic circuit board is the clever arrangement of conductive pathways, or traces, that facilitate the efficient transfer of electrical signals between various components. These traces, often composed of copper, are imprinted on non-conductive materials to create multilayered boards that can minimize the use of space and maximize efficiency. Alongside these traces are components such as resistors, capacitors, and transistors, each responsible for specific functions within the circuit.

Understanding the principles of electronic circuit boards opens opportunities for improved design, troubleshooting, and innovation. With a rapidly evolving technological landscape, the importance of these boards will only increase. Let’s dive deeper into these devices to better comprehend their role in electronics and discover the engineering marvels that enable the functionality we often take for granted.

Electronic Circuit Board Components

Electronic circuit boards consist of several key components that work together to enable the functioning of various electronic devices. The main elements include resistors, capacitors, transistors, diodes, and integrated circuits.

Resistors

Resistors are passive components that limit electrical current in a circuit. They convert electrical energy into heat and come in various types:

- Fixed resistors: maintain a constant resistance value

- Variable resistors: resistance can be adjusted manually

- Thermistors: resistance changes with temperature

Common resistor values are typically measured in ohms (Ω).

Capacitors

Capacitors store electrical energy and release it when needed. They consist of two conductive plates separated by an insulating material called a dielectric. Capacitors are often used in electronic circuits for:

- Filtering: smooth out voltage and current fluctuations

- Coupling and decoupling: isolating signal paths or voltage supply lines

- Timing: creating time delays in circuits

Capacitor values are measured in farads (F).

Transistors

Transistors are fundamental components in electronic circuits, acting as a switch or an amplifier. There are two basic types of transistors:

- Bipolar Junction Transistors (BJT): current flow depends on both current and voltage applied

- Field-Effect Transistors (FET): current flow depends on voltage applied

Transistors are commonly used in digital logic circuits, power amplifiers, and voltage regulators.

Diodes

Diodes are semiconductor devices that allow current to flow in one direction, acting as a one-way valve for electricity. They have two terminals, an anode and a cathode. Common types of diodes include:

- Rectifier diodes

- Zener diodes

- Light Emitting Diodes (LEDs)

Diodes are often used for rectification, voltage regulation, and switching applications.

Integrated Circuits

Integrated circuits (ICs) are chips containing multiple electronic components like transistors, diodes, resistors, and capacitors, which are fabricated on a single piece of semiconductor material. ICs are classified based on their functionality:

- Analog ICs: continuous signals, e.g., audio amplifiers and communication devices

- Digital ICs: discrete signals, e.g., microprocessors and memory chips

- Mixed-signal ICs: combination of analog and digital functionality

ICs are crucial components in modern electronics, enabling complex operations and reducing overall component count in the circuit.

Types of Electronic Circuit Boards

An electronic circuit board is the foundation of every electronic device, supporting and connecting various components in a specific arrangement. There are three main types of electronic circuit boards: Single-Sided, Double-Sided, and Multilayer.

Single-Sided

Single-Sided circuit boards are the simplest and most common type. They have components on one side and conductive copper tracks on the other. These boards are suitable for basic electronic projects and are cost-effective. Some advantages include:

- Low cost

- Simpler manufacturing process

- Easier to repair

However, single-sided boards have limited design flexibility and may not be suitable for complex circuits.

Double-Sided

Double-Sided circuit boards have components and conductive tracks on both sides, increasing the board’s density and capability. These boards are suitable for more advanced projects and are preferred for most commercial applications. Advantages include:

- Greater design flexibility

- Increased component density

- Reduced board size

The primary drawback is the higher manufacturing cost compared to single-sided boards, but the advantages generally outweigh the cost for more complex projects.

Multilayer

Multilayer circuit boards consist of three or more layers, with conductive tracks and connections on the inner layers. They are used for high-density and high-performance electronic devices. The primary benefits are:

- High component density

- Improved signal integrity

- Reduced electromagnetic interference (EMI)

Multilayer boards have a more complex manufacturing process, resulting in higher costs, but they are essential for advanced electronics and high-speed applications.

Manufacturing Process

Design

The first step in the electronic circuit board manufacturing process is the design. Engineers create a blueprint or schematic of the desired circuit using specialized software. This software generates files needed for further manufacturing stages, like the Gerber file and the Bill of Materials (BOM). The design must meet specific requirements, such as performance, size, power consumption, and heat dissipation.

Fabrication

The fabrication process converts the design files into a tangible circuit board. The process involves:

- Substrate preparation: The base material (usually, FR4) is cut and prepared for layering.

- Layering: Copper layers are laminated to the substrate using heat and pressure.

- Photoresist and imaging: A photosensitive layer is applied to the copper layer, and a mask is used to transfer the circuit pattern from the design files. Ultraviolet light hardens the photoresist, and the exposed areas are etched away, leaving behind the copper traces.

- Drilling: Holes are drilled through the board to connect different layers and provide mounting points for components.

Assembly

The final stage in the manufacturing process is assembly. Components are mounted on the board and electrically connected. There are two main methods for assembling electronic circuit boards:

- Through-hole technology (THT): Components with leads are inserted through holes in the board and soldered on the other side.

- Surface-mount technology (SMT): Components are placed directly on the board surface and soldered using solder paste and a reflow oven.

Automated machines are often used for assembly, especially for high-volume production. Quality control tests, like visual inspection and electrical testing, ensure that the manufactured boards meet the design specifications.

Testing and Quality Control

Visual Inspection

Visual inspection is an integral part of assuring the quality of electronic circuit boards. During this process, inspectors check for:

- Component placement: Ensuring that all components are placed accurately in their designated positions.

- Soldering quality: Examining the solder joints for possible issues such as cold solder, solder bridges, or insufficient solder coverage.

- Surface defects: Identifying any visual defects on the board surface, such as scratches, cracks, or contamination.

There are two primary methods used for visual inspection:

- Manual inspection: Involving a trained technician who carefully examines the circuit board for inconsistencies.

- Automated Optical Inspection (AOI): Utilizing advanced imaging equipment and software to automatically detect defects on the board.

Functional Testing

Functional testing is performed to ensure that the electronic circuit board is operating as per its intended design and specifications. This is achieved through a series of tests, including:

- In-circuit testing (ICT): A method where each component is individually tested for functionality and correct values while still mounted on the board.

- Flying probe testing: A non-invasive testing process that involves moving test probes across the board to check for opens, shorts, and component value discrepancies.

- System level testing: A comprehensive test that simulates the actual operating conditions of the board when integrated into its target system.

Functional tests are designed based on the specifications provided by the manufacturer, which might include voltage, current, temperature, and timing parameters. By conducting these tests, it is ensured that the electronic circuit board will function as expected in real-world applications.

Applications and Industries

Consumer Electronics

Electronic circuit boards are an essential component in modern consumer electronics, such as smartphones, laptops, and televisions. They provide the necessary infrastructure for these devices to function effectively and efficiently. With the increasing demand for compact and robust gadgets, circuit boards have evolved to accommodate advanced functionality while reducing their size and weight.

Telecommunications

In the telecommunications industry, electronic circuit boards play a vital role in transmitting and receiving signals, data processing, and ensuring seamless communication. They are found in devices like routers, modems, and cell towers, enabling high-speed connectivity and reliable performance. As technology advances, circuit boards continue to improve, enabling faster communication and greater bandwidth for data transmission.

Aerospace and Defense

The aerospace and defense industries rely heavily on electronic circuit boards for various applications, from flight control systems to advanced weapons systems. These industries require high-quality, ruggedized circuit boards that can withstand extreme temperatures, pressure, and vibrations, ensuring reliable performance in challenging environments. Circuit boards also contribute to the miniaturization and weight reduction of aerospace and defense equipment, essential factors for efficient operation and fuel consumption.

Medical Devices

Electronic circuit boards are crucial in the medical device industry, as they enable medical professionals to diagnose and treat various illnesses and conditions accurately. Circuit boards are found in equipment such as patient monitors, diagnostic imaging machines, and surgical instruments. As medical technology advances, electronic circuit boards will continue to evolve, enabling the development of more sophisticated medical devices, improving patient care, and increasing the efficiency of healthcare services.

Future Innovations

Flexible Electronics

Flexibility is vital for modern electronics to expand into new applications, such as wearables and foldable devices. Recent advances in flexible electronics have paved the way for bendable and stretchable circuits, enabling the development of innovative gadgets. Examples include:

- Conductive polymers that maintain their electrical properties under strain

- Stretchable sensors for monitoring biometric data, such as heart rate and muscle movement

- Flexible batteries that can store and deliver energy while maintaining their structural integrity.

Environmentally Friendly Materials

The impact of electronic waste on the environment is a growing concern. As a result, researchers and manufacturers are focusing on the use of environmentally friendly materials in the design of electronic circuit boards. These innovative materials could lead to:

- Biodegradable substrates, which decompose naturally, reducing waste

- Non-toxic semiconductors that replace harmful elements such as lead and cadmium

- Recyclable components that can be re-used in new circuit boards, reducing the need for raw materials

The shift towards flexible electronics and environmentally friendly materials will undoubtedly contribute to the continued evolution of electronic circuit boards and their applications. With these advancements, we can expect a future where electronics seamlessly integrate into our daily lives while minimizing their impact on the environment.