The world of electronics has experienced rapid advancements in recent years, due in large part to the innovations in printed circuit board (PCB) manufacturing. PCBs serve as the foundation for nearly every electronic device, from smartphones to medical equipment. Increasingly sophisticated technology requires more precise and efficient circuit boards, driving the demand for reliable PCB manufacturers.

To meet this growing demand, PCB manufacturers employ cutting-edge techniques and materials to produce boards with faster processing speeds, lower power consumption, and higher reliability. These manufacturers rely on state-of-the-art software, machinery, and skilled engineers to achieve the desired product specifications. This process includes design, fabrication, assembly, and testing, to ensure the PCB meets the necessary functionality and performance standards.

As the range of applications for electronics continues to expand, the importance of collaboration between PCB manufacturers and device designers is becoming increasingly essential. By combining their expertise and working together, manufacturers can better accommodate the industry’s evolving needs, ultimately contributing to the advancement of the electronics ecosystem as a whole.

Overview of PC Board Manufacturers

PC board manufacturers play a crucial role in the electronics industry by producing printed circuit boards (PCBs) that serve as the foundation for various electronic devices. The process of manufacturing PC boards involves creating an electrical circuit on a non-conductive substrate using conductive material. This section discusses the market leaders in this industry and the types of manufacturers that exist.

Market Leaders

Some of the prominent market leaders in the PC board manufacturing industry are:

- Molex: A global leader in manufacturing interconnect solutions, including PCBs.

- TE Connectivity: Specializes in highly engineered and customized electronic components, including PCBs.

- Amphenol: A multinational corporation known for producing a broad range of interconnect products, including PC boards.

- TTM Technologies: One of the largest PCB manufacturers globally, with a focus on delivering advanced technology solutions.

These industry frontrunners demonstrate expertise in manufacturing high-quality PCBs, ensuring their products meet or exceed customer expectations in various sectors.

Types of Manufacturers

There are different types of PCB manufacturers, each with its unique approach and offerings:

-

Full-Service Manufacturers: These companies handle the entire process of designing, manufacturing, and assembling PCBs. They cater to a broad range of customers and industries, providing an all-in-one solution.

-

Prototype Manufacturers: These manufacturers specialize in creating small quantities of PCBs for testing purposes and refining the design before mass production. They are well-equipped to handle rapid turnaround times and focus on the needs of clients working on new product developments.

-

High-Volume Manufacturers: These manufacturers are capable of producing large quantities of PCBs for mass production. Their strong suit is producing consistent, high-quality products at scale, minimizing cost while maintaining quality.

-

Specialized Manufacturers: These manufacturers cater to niche industries and applications that require specific expertise, materials, or production capabilities. They often work with clients in industries such as aerospace, medical, and defense, where PCB requirements are more stringent.

PC board manufacturers serve a pivotal role in the global electronics market. The industry features a wide range of manufacturers, each with its specialty, be it full-service solutions, prototypes, high-volume production, or niche market expertise. This diversity ensures the availability of a suitable partner for virtually any PCB requirement.

PC Board Manufacturing Process

Design and Prototype Development

The first step in the PC board manufacturing process is design and prototype development. During this phase, engineers create a digital blueprint of the circuit board, including the placement of components, traces, and vias. They use specialized PCB design software to ensure that the design meets electrical and signal integrity requirements.

Once the design is complete, a prototype is created. This is crucial because it allows for testing and analyzing the initial design and to identify any potential issues before moving onto the next phase. Engineers may use different prototyping methods such as:

- Breadboards

- Stripboards

- PCB prototypes

Fabrication

The fabrication phase involves turning the design blueprint into a physical PC board. The process typically consists of:

- Selecting the board material, typically FR4 (a fiberglass-epoxy composite) or a flexible polyimide material.

- Laminating the board with copper layers. The number of layers will depend on the complexity of the design.

- Transferring the design onto the board through a photolithography process, that uses a light-sensitive film to print the circuit patterns.

- Etching away the unwanted copper using chemical solutions, leaving only the designed traces.

- Drilling holes for vias or through-hole components and plating them with copper.

- Applying solder mask to protect the exposed copper traces and adding silkscreen printing for component labels and other information.

Assembly

After fabricating the PC board, the next step is assembly. This involves attaching electronic components to the board. There are two primary methods:

- Surface Mount Technology (SMT): Components are mounted directly onto the surface of the PCB using various soldering techniques.

- Through-Hole Technology (THT): Components are inserted into pre-drilled holes on the board and soldered in place on the opposite side.

SMT is generally preferred as it allows for higher component density, better performance, and faster assembly. However, THT can still be preferable for some designs, particularly when using large or heavy components that may require stronger mechanical attachments to the board.

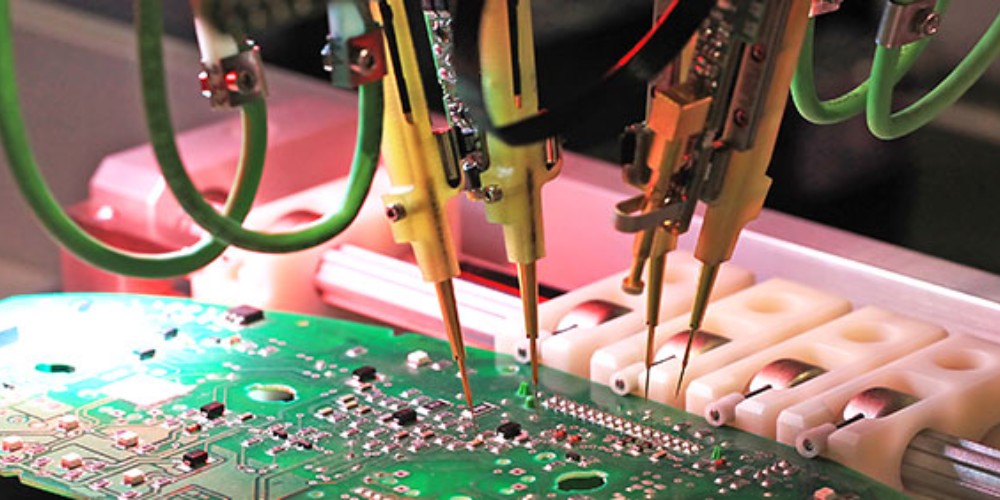

The assembly process may be automated using machines like pick-and-place robots and wave soldering equipment, or it can be done manually by skilled assemblers. Once all components are in place, the boards are subjected to thorough quality control inspection and testing to ensure reliable operation.

Selecting the Right Manufacturer

Certifications and Compliance

Before choosing a PC board manufacturer, it’s crucial to verify their certifications and compliance with industry standards. Look for certifications such as:

- ISO 9001: Ensures consistent quality management systems

- IPC: Demonstrates adherence to industry standards for electronics manufacturing

Verify that the manufacturer complies with environmental regulations, such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals).

Turnaround Time

Turnaround time is a key factor in selecting the right manufacturer. Manufacturers should offer clear and accurate lead times. Be sure to consider:

- The manufacturer’s capacity for handling your project’s volume

- The supplier’s relationships with component suppliers

- Whether the company can handle both small-scale prototyping and large-scale production runs

Comparing lead times will provide insight into a manufacturer’s efficiency and reliability, ensuring your project remains on schedule.

Cost Considerations

Finally, consider the total cost of working with a given manufacturer. Key factors to evaluate include:

- Setup fees

- Tooling costs

- Per-unit prices for various order quantities

- Shipping and handling fees

Keep in mind that the lowest price may not always be the best option. Ensuring high-quality boards and reliable service should be the primary focus. Assess each manufacturer’s cost structure in relation to their reputation, quality assurance processes, and customer service.

Industry Trends in PC Board Manufacturing

Automation and Robotics

The PC board manufacturing industry has been experiencing significant advancements in automation and robotics. These developments have resulted in a more efficient and precise production process. Automated systems, such as pick-and-place machines and robotic arms, have become increasingly prevalent in PCB assembly lines. These machines enable:

- Faster production speeds

- Reduced human error

- Enhanced quality control measures

Moreover, the implementation of artificial intelligence (AI) and machine learning algorithms has further optimized the manufacturing process by allowing machines to learn and adapt to new production techniques.

Sustainability and Waste Reduction

Another noteworthy trend in PC board manufacturing is the growing focus on sustainability and waste reduction. Manufacturers are seeking to:

- Minimize their environmental footprint

- Comply with industry regulations

- Cater to consumer demand for eco-friendly products

To achieve this, they are employing various strategies such as:

- Using lead-free materials and environmentally-friendly alternatives

- Recycling and repurposing waste materials

- Integrating energy-efficient practices throughout the production process

Ultimately, these efforts contribute to a cleaner, greener, and more sustainable PC board manufacturing industry.