Have you ever been curious about how a tiny, seemingly insignificant resistor can play such an important role in the functioning of electronics and circuits? Well, that is exactly what this blog post will be exploring – the mysterious world of surface mount resistors and their key role in circuit board assembly. Surface mount resistors are common components found on almost all printed circuit boards today, but do you really understand what they are and why they’re essential to electronic devices? We’ll explain everything from basic principles to advanced applications for these remarkable little parts so you’ll have a better understanding of what makes them excel at their job!

Definition of a Surface Mount Resistor

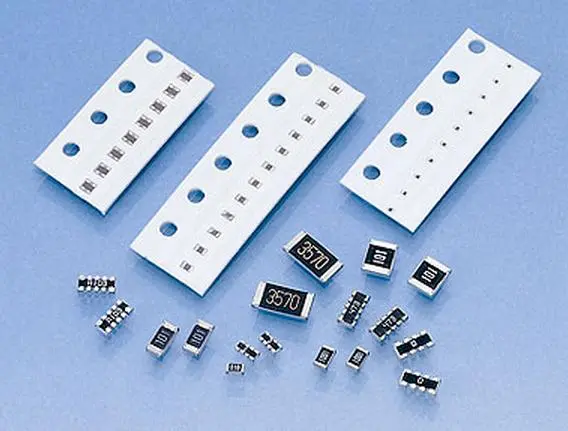

A surface mount resistor is a type of electronic component that is used in circuits to control the flow of electrical current. Unlike its through-hole counterpart, the surface mount resistor is mounted directly onto the surface of a circuit board, which allows for a compact and highly efficient design. These resistors come in a variety of sizes and shapes, ranging from tiny chips to larger rectangular components. Additionally, surface mount resistors are constructed using different materials and techniques in order to meet the diverse needs of various electronic applications. With their advanced design and reliability, surface mount resistors are crucial components in modern electronic devices.

Benefits of Using a Surface Mount Resistor

When it comes to designing and building electronic circuits, there are several components that are essential. One of these components is the surface mount resistor. The surface mount resistor is an electronic component that has a wide range of benefits that make it a popular choice among engineers and hobbyists alike. The main advantage of the surface mount resistor is its size. Because it is so small, it takes up very little space on a circuit board, which is ideal for products that need to be compact. Another benefit of the surface mount resistor is its ability to dissipate heat quickly. This means that it can handle high temperatures without overheating or breaking down. Plus, with its low profile and easy-to-solder construction, the surface mount resistor is a reliable and cost-effective choice for electronic designers.

Different Types of Surface Mount Resistors

Surface mount resistors are an essential component in the electronic industry. They are small in size and designed to be mounted directly onto a printed circuit board, making them ideal for compact electronic devices. There are various types of surface mount resistors available, each with its unique features and advantages. Some of the most common types include thick and thin film resistors, chip resistors, and high power resistors. Thick and thin film resistors are popular for their excellent stability and precision, while chip resistors are known for their small size and high accuracy. High power resistors, on the other hand, can handle large amounts of power without overheating. With so many options to choose from, it’s essential to carefully consider the application and requirements before selecting a surface mount resistor.

How to Choose the Right One for Your Project

When it comes to picking the right surface mount resistor for your project, there are several factors to consider. First, you’ll need to determine the resistor’s parameters, including its resistance value, power rating, and tolerance. Next, you’ll want to carefully evaluate the resistor’s package size, shape, and mounting style to ensure it will fit securely on your circuit board. Additionally, you should take into account the environmental conditions that your resistor will be exposed to, such as temperature, humidity, and vibration. By considering all of these factors and doing your research, you can be confident that you’ve chosen the best surface mount resistor for your specific project needs.

Installation Tips for Surface Mount Resistors

When it comes to circuit board assembly, surface mount resistors are a common component that can trip up even experienced technicians. While they offer numerous benefits such as space efficiency and improved electrical performance, installing them can be a challenge. Fortunately, there are a few tips and tricks that can make the process easier. For example, taking the time to properly clean the board before installation can prevent contamination that could interfere with the resistor’s performance. Additionally, using a microscope or magnifying glass can help ensure accurate placement and soldering. By following these and other installation tips, you can ensure that your surface mount resistors are properly installed and ready to deliver top-notch performance.

Troubleshooting Common Problems with Surface Mount Resistors

Surface mount resistors may seem small and insignificant, but they play a critical role in electronic devices. Unfortunately, they can also cause headaches if they start to malfunction. Troubleshooting these common problems can be frustrating, but it’s important to identify issues as soon as possible to prevent further damage. Some of the most common problems with surface mount resistors include open circuits, short circuits, and resistors that have drifted from their intended values. While these problems can be tricky to address, experienced technicians have a range of tools and techniques at their disposal to get things back on track. So don’t panic if you encounter issues with your surface mount resistors – there are solutions out there.

In conclusion, surface mount resistors are becoming increasingly commonly used components in electronic circuits and devices. They are generally smaller, more reliable, and more resistant to thermal fluctuations than their through-hole counterparts. While the variety of resistor types can be overwhelming at times, it is important to carefully consider the details of your project before selecting the right one. As long as you understand the differences between each type of surface mount resistor and choose accordingly, installation should be easy. Additionally, understanding common issues can help mitigate them quickly and minimize any disruption to the project plan or timeline. Ultimately, the planning that goes into selecting an appropriate component with proper installation pays off in time when everything runs smoothly.