Get the packaging of an Integrated Circuit (IC) right and you have done a half of the job to keep the components safe. Get it wrong and all your efforts to protect the semiconductor components and improve the circuit’s performance go out of the window.

When it comes to packaging an Integrated Circuit (IC), one of the options out there is the CPGA. This blog post details what a CPGA means and why you should probably consider this type of packaging for your circuit-based devices.

What is CPGA?

CPGA is the shortened name for Ceramic Pin Gate Array. It is one of the packaging options for ICs and is based on the Pin Gate Array (PGA) family.

The IC packages under PGA are known for several features, including the simplicity of configuration, multiple lid options and a few placement options.

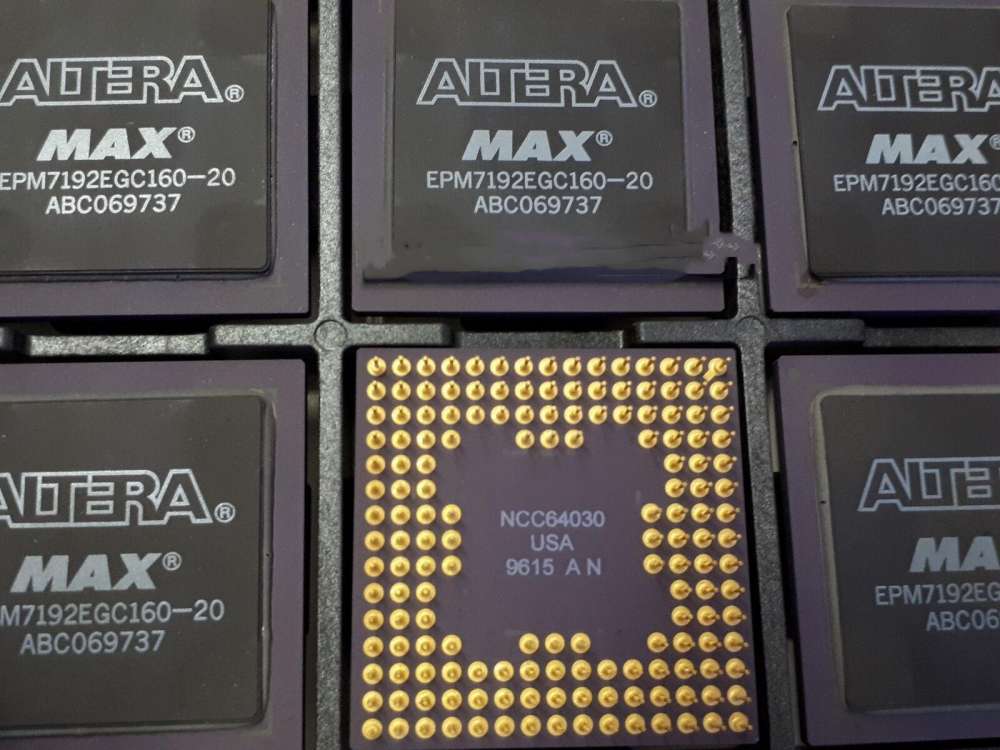

On its part, the CPGA uses a ceramic substrate and has the pins arranged in the pin grid array. We also like to mention that the CPGA can either take the rectangular or square shapes. The packaging also has the pins arranged squarely at the bottom of the body.

Attributes of the Ceramic Pin Gate Array (CPGA)

One remarkable feature of the CPGA is the logical arrangement of the pins to be in the form of a square array and arranged at the bottom of the package.

These pins are not the only remarkable attribute of the package. Here are some of the additional features to look out for:

1. Lid Sealing Style

It is common to seal the lid of the Ceramic Pin Gate Array (CPGA) with either the “solder seal” or the “frit seal.”

2. Excellent Spacing

The amount of space between component A and component B inside a semiconductor can make all the difference in the optimization.

In the case of the CPGA, we have its spacing estimated at 2.5mm apart, which is the same thing as 100 mile apart.

Such adequate spacing makes placing more components easier. It can also help in preventing these components from overlapping in performance.

3. CPGA has Several Use Cases

Having an IC package is much more than protecting the semiconductor components. The package also comes in handy when optimizing the Printed Circuit Board (PCB) for the specific applications.

CPGA use cases are primarily for the devices requiring a higher Input and Output (I/O) processing signal.

It is also one of the best IC packages for devices requiring an improved thermal performance, as well as high-speed.

Little wonder the CPGA IC package has been adopted across different applications and become a favorite for some top brands. Example of a brand that has used the package is AMD.

In the case of AMD, the CPGA was used to in the following cases:

4. AMD-Based Processors

CPGA has found its way into packaging some of the processors manufactured by AMD. The circuit board manufacturer (AMD) used the CPGA on its Socket AM2 and SocketAM2+ processors.

Athlon Processors

AMD also used CPGA on its Athlon and Duron processors. These processors were based on the AMD Socket A.

High-Speed Applications

Gate arrays and PC chip sets find using the CPGA IC package satisfactory, but that is just a tip of the iceberg. The package has since been used to protect the semiconductors of the following:

- High-speed performance devices, such as Personal Computers (PCs), and laptops.

- Controllers

- ASICs

- Microcontrollers (MCUs)

- DSPs

- Memory

5. Multiple Soldering Options

As the Ceramic Pin Gate Array (CPGA) is placed at the bottom of the package, soldering the same into place would be the best way to go about it.

To that end, designers have an array of options to choose from, notable among which are soldering the CPGA via the PGA socket or through the through-hole pathway.

If you are working with the Through-Hole Technology (THT), the process would typically require passing the package through the hole.

On the other hand, using the PGA socket could prove a simpler option. All you have to do is to insert the CPGA into the PGA socket for it to be placed at the designated point on the board.

6. Flexible Pin Counts

One of the downsides to working on a Printed Circuit Board (PCB) is not having enough pins to use. If you are working with the CPGA, rest assured that the issue may be swiftly tackled, thanks to the flexibility of the pins.

The pins range from 28 and 476 and can fit into the varied body sizes of 50 mil and 100 mil pin pitches.

What’s more? CPGA has an expanding package offering, meaning that you get to choose from other variants that have more pin counts.

7. Excellent Thermal Performance

Managing heat dissipation on the board is excellent, thanks to the several options the package presents. For example, it offers the following heat dissipation options:

- Heat sink

- Heat plate

- Heat slug

8. Custom Enhancements

Ceramic Pin Gate Array (CPGA), apparently, is one of the few Integrated Circuit (IC) packages offering customizations. The varieties of custom performance enhancements are readily available to help the designer further expand the overall performance of the package.

The custom enhancements are specifically targeted at improving the additional electrical and thermal requirements demanded by advanced electronics.

9. Integrated Design

CPGA is more like a full-suite IC package, offering an integrated design that enables the enhanced performance of the semiconductor technologies.

CPGA Alternatives

For some reasons, you may not want to package your semiconductor or circuit board with the Ceramic Pin Gate Array (CPGA).

That’s fine. You can use alternatives under the Pin Gate Array (PGA) IC package. The popular variants are:

Organic Pin Gate Array

Also known as OPGA, this type of Pin Gate Array is used when working on applications that require the placement of the silicon die to the plate made out of an organic plastic.

Flip Chip Pin Gate Array (FCPGA)

This type of Pin Gate Array (PGA) works by allowing the silicon die to have a direct connection to any cooling mechanism on the circuit board – especially to the heatsink.

Conclusion

Using a Ceramic Pin Gate Array (CPGA) guarantees improved thermal performance, excellent pin spacing and optimization for the high-speed applications.